With its worldwide production sites and service offerings, the company comprehensively supports vehicle manufacturers in optimizing their products and processes and meeting the highest quality standards. At this year's Battery Show Europe, which will take place from June 28 to 30 in Stuttgart, Germany, the adhesive specialist will primarily present adhesive solutions for optimal thermal management and reliable electrical management in the battery.

With its worldwide production sites and service offerings, the company comprehensively supports vehicle manufacturers in optimizing their products and processes and meeting the highest quality standards. At this year's Battery Show Europe, which will take place from June 28 to 30 in Stuttgart, Germany, the adhesive specialist will primarily present adhesive solutions for optimal thermal management and reliable electrical management in the battery.

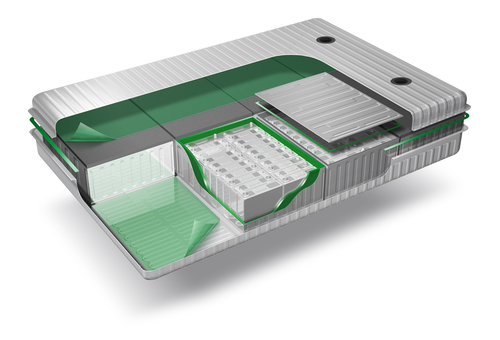

With increasing electromobility and the rapidly growing market for EV batteries, many new challenges also arise for bonding that go far beyond reliable joining per se. For example, the optimum efficiency and maximum service life of lithium-ion cells are achieved at a temperature of 20° to 35° Celsius. Therefore, optimal thermal management is a prerequisite for the proper functioning of the EV battery. The thermally conductive Lohmann adhesive tapes of the DuploCOLL® TC range allow efficient connections to be made to the cooling or heating element of the battery.

EMI shielding is mainly about shielding electromagnetic waves in the best possible way to avoid interference and disturbance of an electrical component. Here, the DuploCOLL® EC series ensures that the electric vehicle's components are optimally shielded, protecting its occupants from the dangers that vehicle malfunctions can bring. The EC range offers shielding attenuation properties across a wide frequency spectrum (450 MHz - 3.8 GHz) and is easy to die-cut and apply

The above examples are just two in Lohmann's long line of innovative adhesive solutions for the design of vehicle components such as EV batteries. The multifunctional adhesive tapes for high-performance bonding are used by automotive OEMs and tiers at many points in the vehicle. As an established partner to the automotive industry, Lohmann is certified to IATF 16949 and has a large number of product approvals from various OEMs. At this year's Battery Show Europe, the company will therefore present itself as a reliable development partner that competently supports the automotive industry's shift towards electrification. Adhesive experts from research and development will be available to answer visitors' questions, as will application engineers and sales staff.

Visit us in hall 8 booth D 35 and convince yourself of our individual approach to solutions.