Therefore we offer the suitable product for every application: For excellent print quality, efficient processes and the best handling. With personal advice, individual solutions and an innovative premium service.

Against the backdrop of a steadily growing packaging industry, flexo printing has established itself in recent decades as a globally successful technique in relief printing. But there is also a great deal of competitive pressure. Complex print jobs, increasing quality demands and narrow time frames are forcing many printing companies to further optimize their production processes.

To benefit from your decisive advantage, Lohmann, as a qualified partner, is at your side - from the first idea to process integration and beyond: Anytime and worldwide. This is what Smart Bonding for Flexo stands for - opimized processes covering the entire range of flexo printing.

DuploFLEX® from Lohmann is a global standard in compressible printing plate mounting

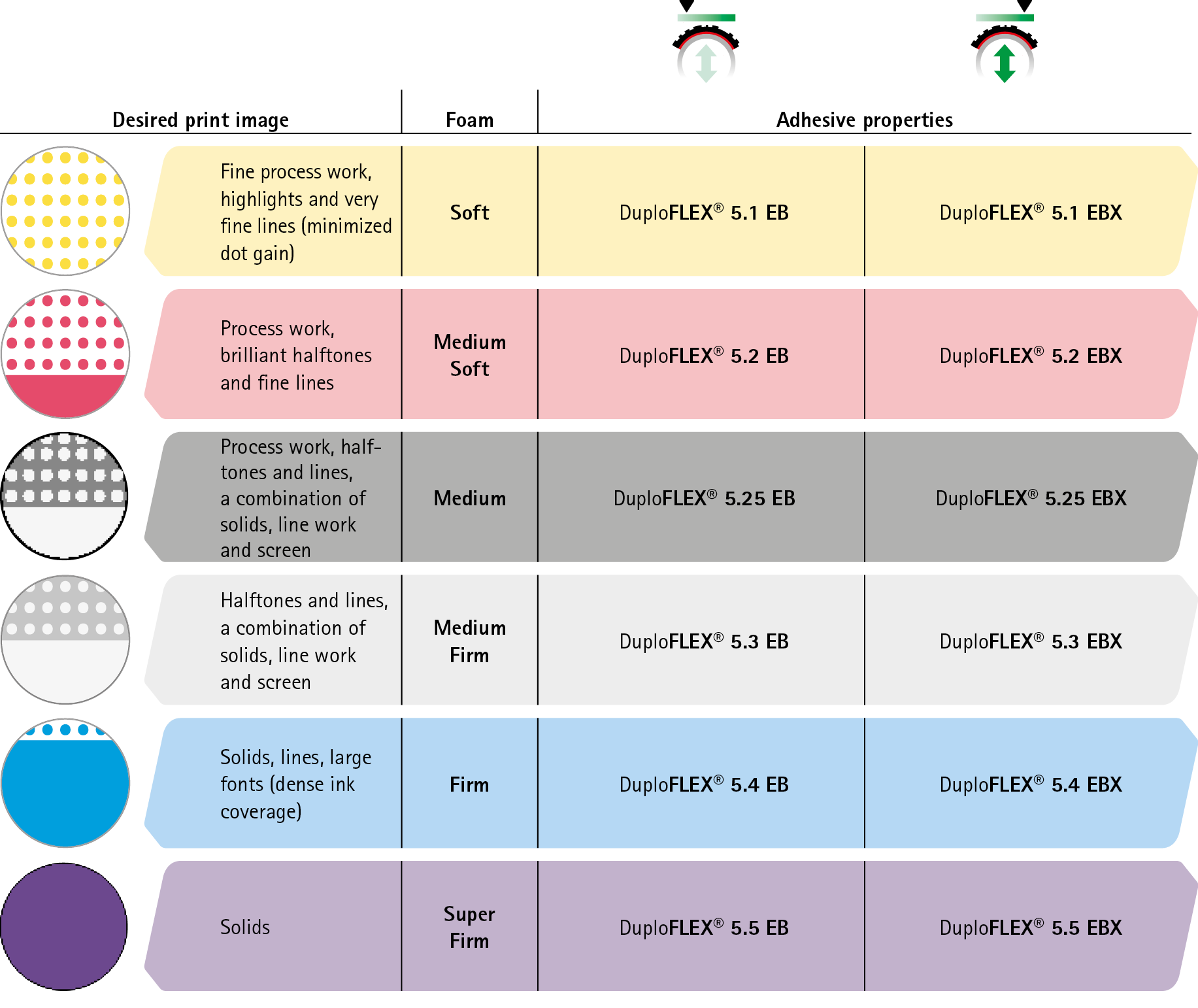

Our DuploFLEX® 5 EB range of adhesive tapes has been specially developed for 0.020" flexo printing and offers you all the benefits demanded from flexible packaging printing. Thanks to a wide range of adhesive tapes with varying foam hardnesses and adhesive properties, you can always call on the perfect product to meet any flexo printing task. You benefit from perfect printing results that give you a decisive advantage over the competition.

A perfect printed image down to the last detail

Fine process work, brilliant half-tones, perfect solids; no matter the printed image, the DuploFLEX® EB 5 range promises excellent results. Use the table below to see what adhesive tapes we recommend for each application.

With six different foam hardnesses and two different sets of adhesive properties, the DuploFLEX® EB 5 range truly gives you the freedom to always make the best choice for each printing job. Storage considerations are also accounted for with individual color-coding on each set of packaging, allowing easy product identification. In addition, all DuploFLEX® packaging is fully recyclable. You can save not only the environment, but your own disposal costs too. Call us today and let our experts answer any questions you may have.

Improved quality from double-sided flexible film

In contrast to conventional foam adhesive tapes with a laminated PET film, our DuploFLEX® 5 EB range features a double-sided flexible PE film layer. This is a key design feature that ensures optimum printing results. It sees that the forces applied to the compressible foam are perfectly cushioned, resulting in no uncontrolled dot gain and an excellent printed image, even at high printing speeds.

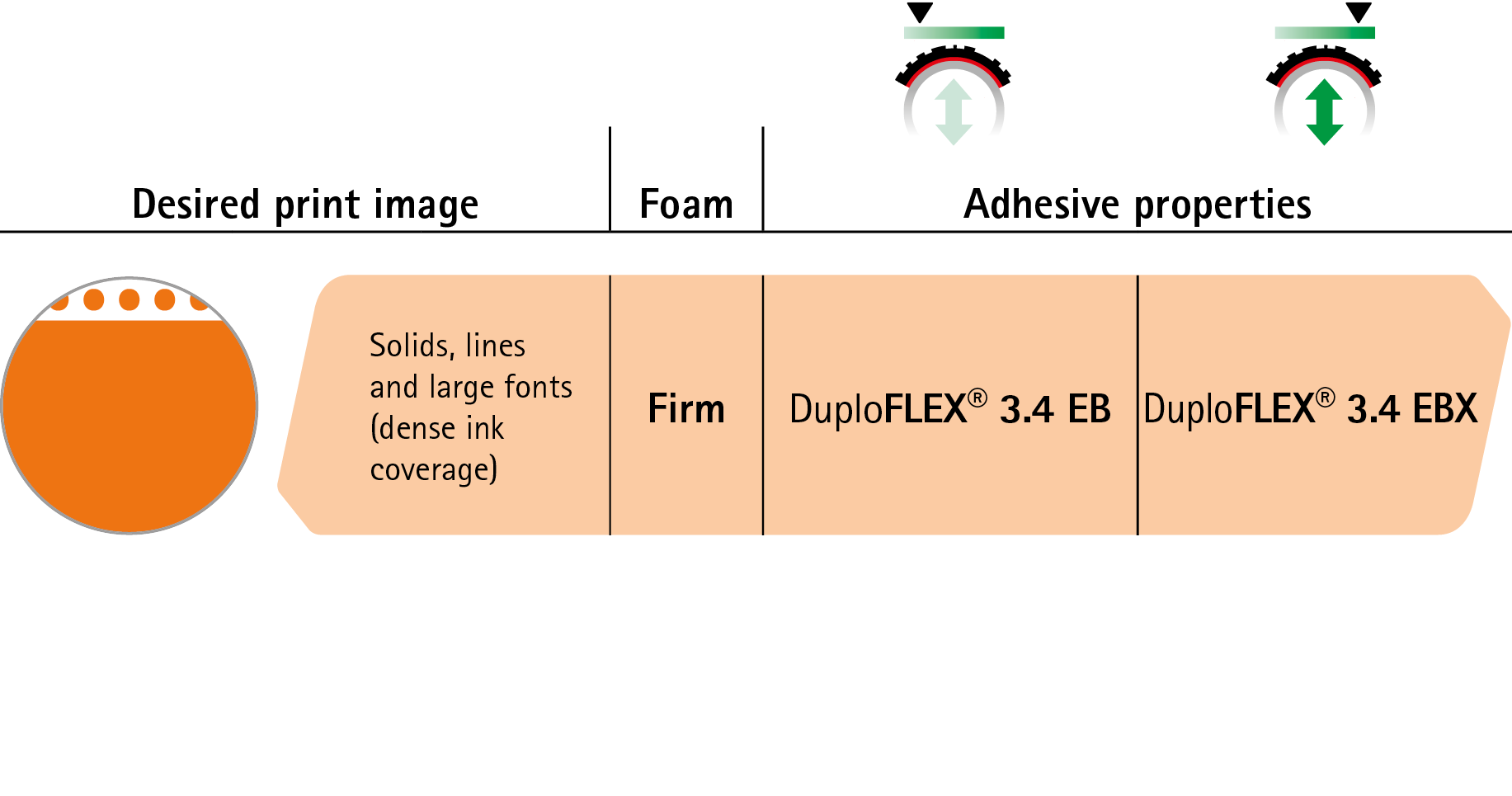

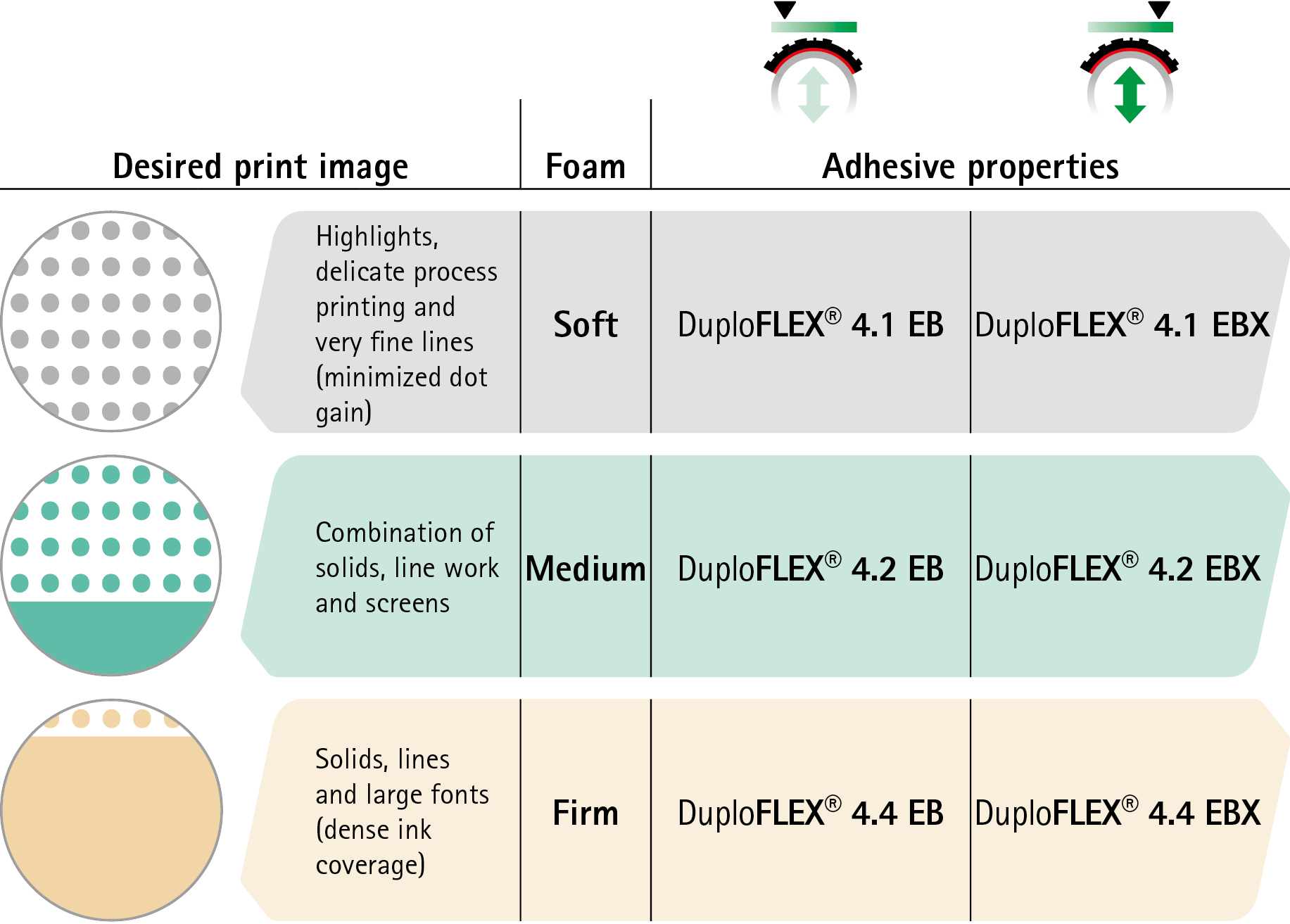

A perfect printed image down to the last detail

Regardless of the printed image you're striving for, DuploFLEX® 3 and DuploFLEX® 4 guarantee excellent printing results in both the 0.015" and 0.017" ranges.

Improved quality from double-sided flexible film

The double-sided flexible film on Lohmann printing plate tape solutions ensures optimum printing results. The forces acting on the compressible foam are perfectly cushioned. Uncontrolled dot gain is prevented and an extremely sharp printed image is achieved - even at low printing pressures.

Meets every need

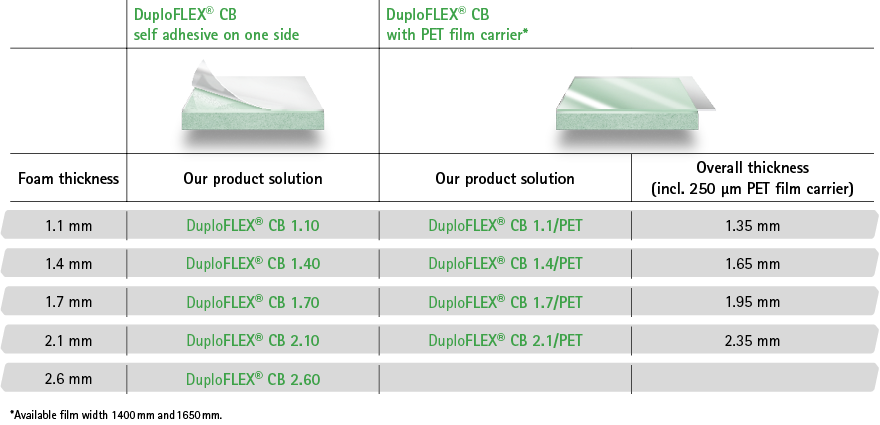

PET film carrier or single-sided adhesive high quality polymer foam – whatever your needs, the DuploFLEX® CB range provides you with the tools to create perfect results in flexographic cardboard box printing.

Practical for your storeroom

Individual colour-coding on each set of packaging allows easy product identification. In addition, all DuploFLEX® packaging is fully recyclable. You can save not only the environment, but your own disposal costs too. Call us today and let our experts answer any questions you may have.

|

FlexoLAB: First simulate, then integrate. Our innovative FlexoLAB shows the major steps on a realistic scale and our mission: Testing, analyzing and optimizing to achieve the best print results for you. Our aim is to map your process from A to Z, then simulate it in the FlexoLAB, so you can achieve the highest possible quality with the help of our customized solutions. The Lohmann FlexoLAB consists of a mounting machine and a print simulator. Want to know more? We analyze your process at our innovative FlexoLAB. |

|

DuploFLEX® Toolbox: Do you want your entire mounting process to be as efficient as possible? Our DuploFLEX® Toolbox offers everything you need. With practical tools for optimum mounting of print jobs. Our DuploFLEX® Toolbox contains:

|

|

Our technical know-how - your benefit. We, the Lohmann Bonding Engineers, are FLEXperts for the entire flexo printing process. Togehter we analyze your requirements, give the right recommendations and find the best solution for you. At any time, worldwide. One of the essentials for an efficient printing process is to know exactly how, where and under what conditions which plate mounting tape shall be used. This is where the experience and know-how of the Lohmann FLEXperts comes into play: We analyze your requirements in detail and find the right solutions with the right parameters. We support you anytime and worldwide regarding all questions you may have concerning your process. |

Interested in finding out more?

Then contact us. We will be pleased to help.

Contact form Flexo printing