For 40 years now, Lohmann has been answering to increasing demands on the market. Customized, certified bonding solutions and high-precision die-cuts for applications in the fields of bio, process, sensor and medical technologies as well as automotive, electronics and consumer goods industries are developed with Lohmann’s “Smart-Bonding-Approach”:

From the initial idea to the final implementation into the customer’s process, the Bonding Engineers are competent partners at their customers’ side. Design and manufacturing are reconciled, if required by means of specially developed machines. Quality assurance, too, is essential to guarantee an error-free and smooth function. Geometrical, with tolerances in a micrometer range, as well as functional. During the entire production process Lohmann leaves nothing to chance.

In order to be able to meet the requirements of their customers for high-precision die-cuts worldwide, experienced Bonding Engineers are available at Lohmann locations all over the world. Concentrated expertise and global die-cutting competence can thus be accessed at any time.

Flatbed die-cutting is one the two most frequently used die-cutting processes, with rotary die-cutting being the second one. Flatbeds are used for a wide range of materials, from lightweight ones such as paper to plastics and IML (In-Mould-Labeling). Flatbed die-cutters are used in particular for processing smaller quantities, for example in packaging and label production.

|

|

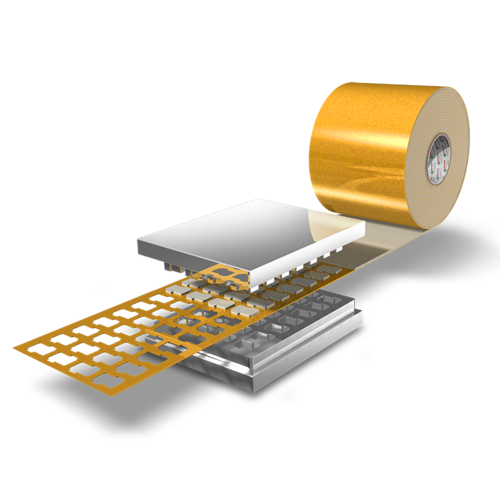

Rotary die-cutting is one of the two standard die-cutting processes, with the second one being flatbed die-cutting. In this process, a cylindrical die rotates on a rotary press. Rotary die-cutting machines can include several stations with various functions that can all be synchronized into the same speed by geared tools to allow for low tolerances.

|

|

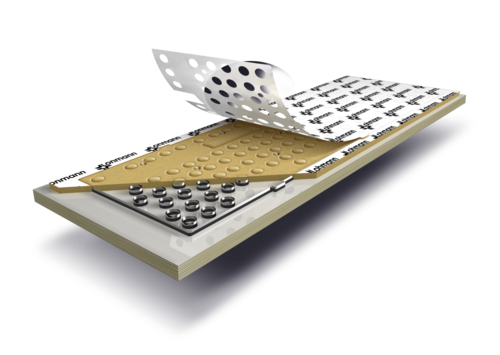

One of the most widely used press systems are full metal dies. These electromechanically driven processing machines are characterized by the relative movement of their tools. Full metal dies are used in the die-cutting process for cutting, embossing or bending, often in short-stroke applications. The lifting force can be variably adjusted and tolerances are narrow.

|

|

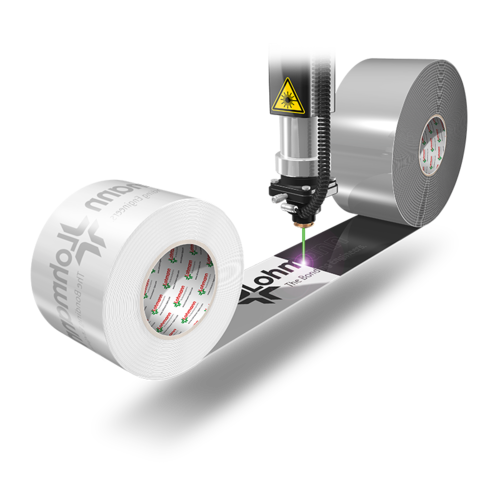

Laser plotters are widely used for prototyping, model and tool making. Because they can be applied to a wide range of materials, they are fit for testing new components and materials and developing prototype groups. Laser plotters work similarly to flatbed die-cutters, with their main functions being marking, cutting or engraving.

|

|

Lohmann’s Competence Center Die-Cutting in Remscheid was founded in 1972. Today, on an area of more 4.000 m² with about 130 employees, the site offers a wide range of converting machines: 16 rotaries (three in cleanrooms), three flatbeds, one full metal die, one central cylinder (in a cleanroom as well), a prototyping and an inline laser, state-of-the-art robotic and measuring devices, fully automated 100% measurement for running processes as well as cleanroom classes for pick & place processes.

Lohmann Remscheid has been certified many times over. Please click here, to find an overview of the certificates.

Cleanroom (class 8)

Then contact us. We will be pleased to help.