The new universal vapor barrier tape

Permanent air- and windtight sealing is getting more and more important for sustainable constructing. For interior applications various adhesive tapes are used by default. Concerning windtight sealing, bonding solutions for exterior applications have to meet even higher demands. Lohmann combines these different bonding requirements in just one single tape.

A true all-rounder

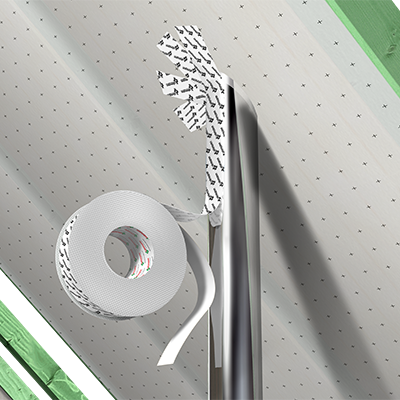

Our tape is an excellent choice for air- and windtight bonds on connections, penetrations and overlaps in the interior and exterior area on a variety of substrates.

The tape is perfect for multifunctional uses. A special smooth carrier allows for keeping track as well as for a good elongation. The newly developed adhesive offers an excellent inital tack and a strong final bonding performance.

Carrier and adhesive are tuned to the exterior conditions. Even in cold weather the initial tack is very good and can be processed at temperatures of down to -10°C.

The Universal-Tape has a high permanent adhesion. Its adhesive formula does without rubber, resin or solvents. It cannot dry out or become brittle. Outdoor exposure - UV stability and waterproofness - up to 12 months is given without covering. Construction movements are compensated reliably and durably.

Identical tape construction in various colors

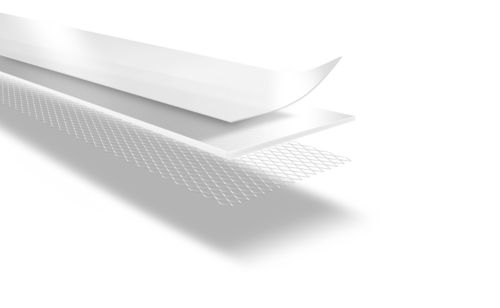

The structure consists of a polyethylene-carrier and a scrim. The adhesive mass is made of a dispersion adhesive with a very strong tack. Because of its excellent initial and final adhesion the Universal-Tape can be used for numerous surfaces.

The tape construction for the transfer version

The tape consists of a scrim, coated on both sides with an extremely strong dispersion adhesive. Due to its excellent initial and final tack the Transfer-Tape can be used for numerous surfaces.

DuploCOLL® 22522 and DuploCOLL® 22523

|

|

|

| Penetration bonding | Sealing exterior roof and facade sheeting | Bonding overlaps and injection holes |

The Universal-Tape is labelled with the GEV seal EMICODE® EC1 for a low-emission construction product. The environmental requirements for VOCs (volatile organic compounds) and emission regulations according to label M1 are fulfilled, too.

We take into account the market requirements and test the bond according to DIN 4108-11. This standard certifies the minimum requirements for the durability of bonds used for airtight layers. For that, the shear strength is examined, especially under difficult conditions as a consequence of an artificial aging process in a climatic chamber.

What‘s more: In addition to testings on the durability of the bond we examine the alternating loads according to procedure B of DIN 4108-11. This includes simulations of the load that effects the bond at maximum wind speed. This test is not obligatory for us but it guarantees our customers an even higher level of safety applying our products.

All-in-One Flyer

All information for you in one handy PDF document. Download here now.

Interested in finding out more?

Then contact us. We will be pleased to help.

|

Customer benefits:

Products:

|

|

Customer benefits:

Products:

|

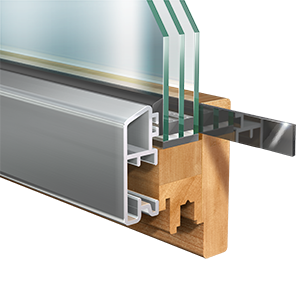

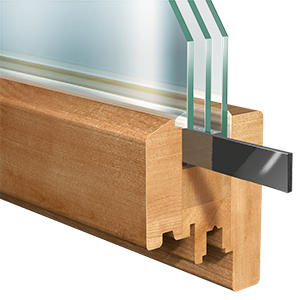

The certified "Static Direct Glazing" (SDG®) with Lohmann adhesive tapes is now even more precise and process-reliable. With our new product variants DuploCOLL® 56056 and 56057 you have, on the one hand, extremely stable film liners that cannot be overstretched. In addition, the glazing process can be considerably simplified – while readjustments of the window pane remain possible until the end.

How does this work?

With the new SDG® adhesive tapes, you only loosen the liner in the corners of the wooden frames before applying the glass pane and remove it completely after you have carried out the final positioning and blocking. Easy handling for a perfect result!

See for yourself:

For further information on SDG® and processing instructions, please download our flyer:

Adhesive bonding on coated wood.pdf

Please have a look at the video below to find out how a RC3 testing looks like:

Contact our Building & Construction experts personally.

Contact us now

For further information or your enquiries, please send us an email. We look forward to hearing from you!