TwinMelt® makes multifunctional product designs and innovative combinations possible: with high material variance in carrier and liner systems and different chemistries, various tape constructions as well as symmetrical and asymmetrical stripe coatings can be realized in just one production step. This saves resources and allows for breathable adhesive coatings, from very low to very high application weights.

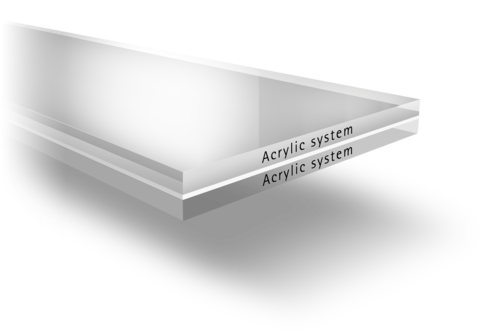

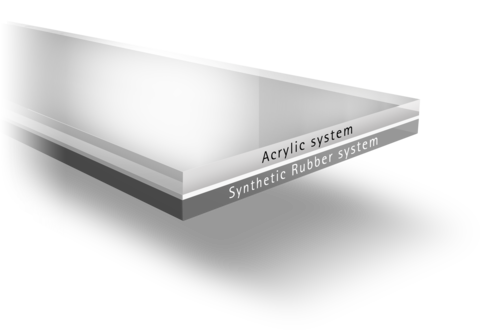

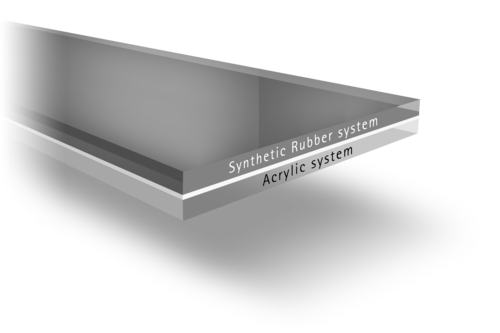

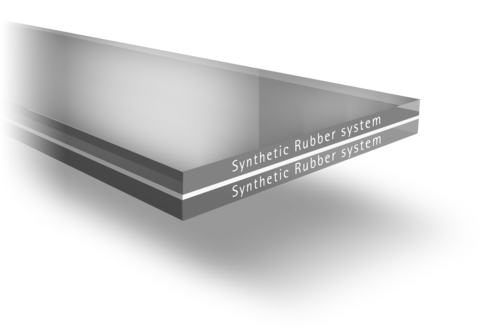

Acrylic and rubber systems form the basis for TwinMelt® technology and enable solvent-free compounds. But they offer much more than that:

| Characteristics Acrylic Systems | Characteristics Rubber Systems |

|

|

he TwinMelt® technology enables us to combine rubber systems and acrylic systems in a wide variety of structures.

|

|

|

|

The technology

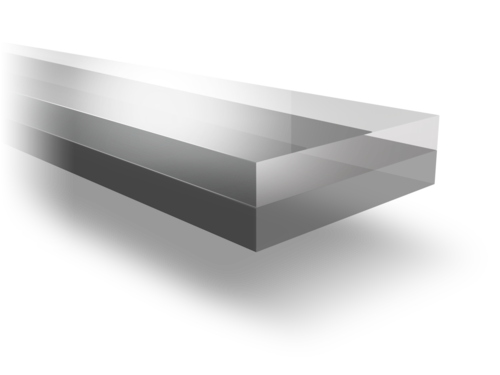

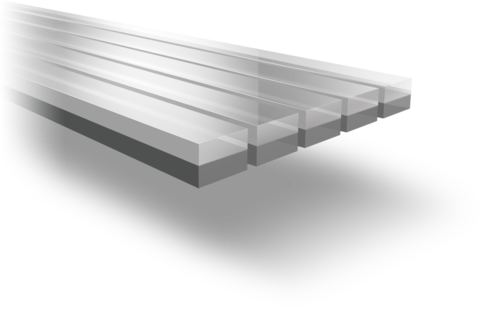

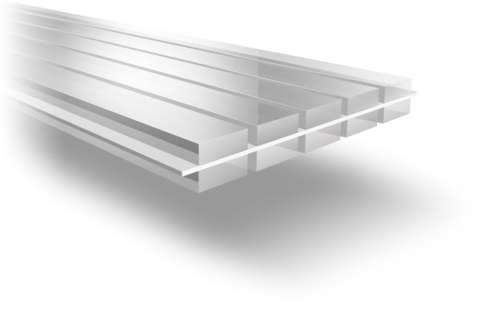

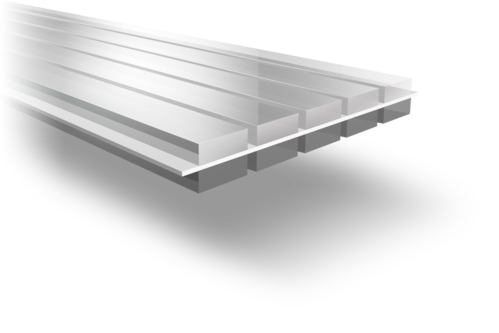

The multifunctional TwinMelt® technology allows for double-sided adhesive tapes based on acrylic and rubber systems to be coated in a smart process – and 100% solvent-free.

Multifunctionality through

The possibilites

The benefits

The possible combinations

|

|

|

|

|

Adhesive system |

Stripe coating asymmetrical, without carrier |

Stripe coating symmetrical, with carrier |

Stripe coating asymmetrical, with carrier |

|

|

|

|

| Stripe coating symmetrically shifted |

Stripe coating symmetrically shifted |

Stripe coating asymmetrically shifted |

Stripe coating/full coating asymmetrical, with carrier |

With TwinMelt®, we are ideally positioned to meet your individual toll coating requirements.

No matter if you want to coat films, textiles or paper: all carrier materials are possible.

With a modular portfolio of various adhesives, we can not only meet your specifications as quickly as possible – Lohmann also develops and manufactures adhesives according to your specific requirements.

Award-winning technology: Rhineland-Palatinate Innovation Award in the category “Special Award of the Minister of Economic Affairs 2023: CO2 Reduction through Innovative Processes and Products” goes to TwinMelt®.

Produced with TwinMelt®: Our new ECO range!

The latest addition to the Lohmann adhesive tape portfolio is the biobased, solvent-free products of the DuploCOLL® ECO range.